Product

Lockout Tagout (LOTO) – What It Is and Why It Matters

Lockout Tagout (LOTO) refers to the isolation and clear marking of hazardous energy sources during maintenance and repair work.

Lockout Tagout (LOTO) – What It Is and Why It Matters

Lockout Tagout (LOTO) refers to the isolation and clear marking of hazardous energy sources during maintenance and repair work. What does LOTO mean in practice, how is it implemented, and why should every industrial company take it seriously?

What does Lockout Tagout (LOTO) mean?

Lockout / Tagout is a safety procedure designed to ensure that machines and equipment remain completely de-energised—and all stored energy released—while they are being serviced or repaired.

Lockout – The power supply or other energy source is isolated (switched off) and physically locked so no one can re-energise the system by accident.

Tagout – A conspicuous warning tag is attached to the lock or isolator stating that the equipment is locked for maintenance and that only the authorised person (normally the technician performing the work) may remove the lock.

Example: A technician is servicing an electric motor.

He first disconnects the motor’s power via the main switch.

He applies his personal padlock; only he has the key.

He attaches a bright tag reading “DO NOT START – Maintenance in progress. Lock applied by: John Smith.”

The motor is now in a locked-out state. Only after John finishes and removes his lock and tag may the motor be energised again.

LOTO covers all forms of hazardous energy—not just electricity, but also compressed air, hydraulic pressure, steam, chemical energy, gravity (falling components) and kinetic energy in moving parts. The procedure includes identifying and releasing these energies: e.g. isolating and locking valves in a steam line and opening drain valves to vent pressure, or mechanically supporting a large gear so it cannot shift.

Why is LOTO so important?

Without a LOTO programme, maintenance personnel face severe risks: a machine can start unexpectedly or stored energy can release suddenly, leading to serious injury or death. Typical accident scenarios that LOTO prevents include:

An electrician is repairing a machine when a coworker—unaware of the work—restores power, causing electrocution or unexpected motion.

A welder inside a tank is suddenly exposed to gas or liquid because someone opens a valve, not realising maintenance is underway.

A mechanic cleaning a large cutter is struck when the blade rotates due to residual kinetic or gravitational energy.

An operator bypasses an interlock to clear a minor jam; the control system automatically restarts once the obstruction is gone, trapping the worker’s hand.

LOTO is therefore vital in industry, power generation and maintenance. In the United States, OSHA mandates it (29 CFR 1910.147, Control of Hazardous Energy). International standards and Finnish occupational-safety legislation impose similar duties: hazardous equipment must be secured before work begins. Statistics show that the absence of LOTO is a root cause of many serious accidents, whereas firms with disciplined LOTO programmes see markedly lower incident rates.

How is LOTO carried out in practice?

A complete LOTO procedure follows these steps every time:

Preparation

The supervisor or worker identifies all relevant energy sources. Plan how to cut electrical power, block motion, discharge stored energy (e.g. capacitor bleed-off, pressure release).Normal shutdown

Stop the equipment using its regular controls (e.g. press STOP). This alone is not sufficient.Isolation

Disconnect every identified energy source: turn the main disconnect to OFF, close valves, lower suspended loads or add mechanical supports, etc.Lockout

Apply LOTO locks to all isolation points—bright, dedicated padlocks. One worker, one lock, one key. For group tasks, use a hasp so each person applies their own lock; the machine cannot be restarted until every lock is removed.Tagout

Attach a warning tag showing the lock owner’s name, contact details and reason for lockout, usually reading “Do Not Start”.Release of stored energy

Even when disconnected, equipment may retain energy. Vent pressure lines, block or brace moving parts, discharge capacitors, etc.Verification (Try-out)

Before beginning the work, test that isolation is effective: attempt to start the machine (it must not start) and measure zero voltage where applicable. Then return controls to OFF.Restoration

When the job is complete, reverse the sequence: verify area is clear, remove each personal lock, inform all parties, re-energise and test normal operation.

Personal lock rule: Each lock is strictly personal. Only the person who applied it may remove it (except under a strict written protocol by a safety manager after verifying the worker is safe and off-site).

Legislation and standards

Finnish Occupational Safety Act (738/2002) § 41 requires preventing accidental start-up and access to danger zones during maintenance—fulfilled in practice by LOTO.

EU Machinery Directive (2006/42/EC) obliges manufacturers to provide means for safe energy isolation (e.g. lockable main switches).

ISO 45001 cites LOTO as best practice for hazardous-energy control.

Insurers often inspect LOTO procedures because unexpected energisation can cause catastrophic losses.

Making LOTO work in an organisation

LOTO demands proper hardware and disciplined culture:

Acquire suitable devices – Padlocks, hasps, circuit-breaker locks, valve locks, plug locks, etc., matched to every isolation point. Issue each worker personal locks and tags.

Clear written procedures – Easily accessible instructions detailing who may lock, how to tag, multi-lock rules, shift-change hand-overs.

Training and drills – Train all maintenance staff, operators and supervisors; demonstrate locking techniques; run emergency drills to ensure no one bypasses LOTO under pressure.

Management commitment – Provide time and resources; resist production pressure that tempts staff to cut corners.

Ongoing supervision – Designate a safety specialist to audit LOTO compliance, conduct spot checks and correct deviations immediately.

Integration with work-permit system – Include a LOTO checklist in every maintenance or work permit: “LOTO plan completed and executed – Yes/No”.

Summary: LOTO saves lives

Lockout Tagout may appear complex, but it is a lifesaving investment for maintenance and repair. Every moment spent isolating and locking energy sources is well spent—it can avert fatal accidents.

In companies where LOTO is routine, workers feel safer; they know no one can accidentally start the machine while they work. Confidence improves morale and productivity.

LOTO is a cornerstone of safety management and fits a broader culture of planning and verification. Combined with robust permit-to-work systems, it ensures hazardous jobs are performed without incident.

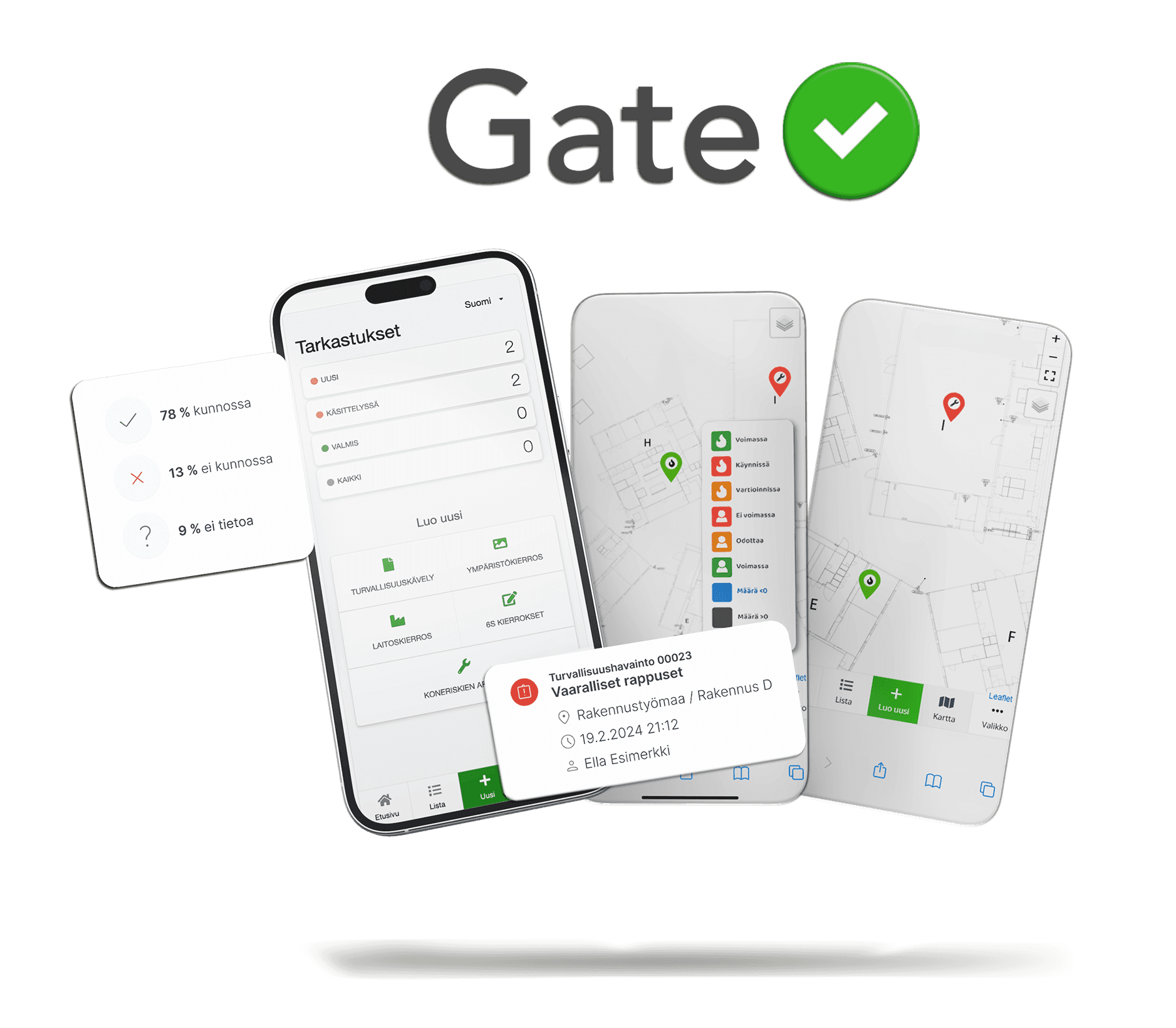

If your site lacks a mature LOTO programme, start developing one now. Guidance is available from standards bodies, training providers and experienced safety engineers. Gate Apps’ permit-to-work solution even allows you to embed LOTO confirmation into each electronic permit.

Want to learn more about implementing LOTO in your environment or how a digital permit system supports the LOTO process? Contact us to book a demo—we’re ready to help you roll out safer practices.