Product

What is an electronic permit-to-work system?

An electronic permit-to-work (PTW) system replaces paper-based permit processes with fully digital solutions.

Electronic Permit-to-Work System

An electronic permit-to-work (PTW) system replaces paper-based permit processes with fully digital solutions. Why should companies adopt an electronic PTW system, and what advantages does it offer over traditional permit management?

What is an electronic permit-to-work system?

An electronic PTW system is a software- or cloud-based platform used to manage all work permits digitally. A work permit is a prior authorisation required for hazardous or specially controlled tasks—such as hot work, confined-space work, working at height, excavations, radiation work, and so on. Whereas these permits were traditionally handled on paper, an electronic system runs the entire process via computers and mobile devices.

The solution may form part of a broader safety-management suite or operate as a stand-alone application. What matters is that

every permit request, approval, condition and acknowledgement is processed inside the system;

information is available in real time to everyone who needs it; and

permits are stored in the system, making later retrieval and review effortless.

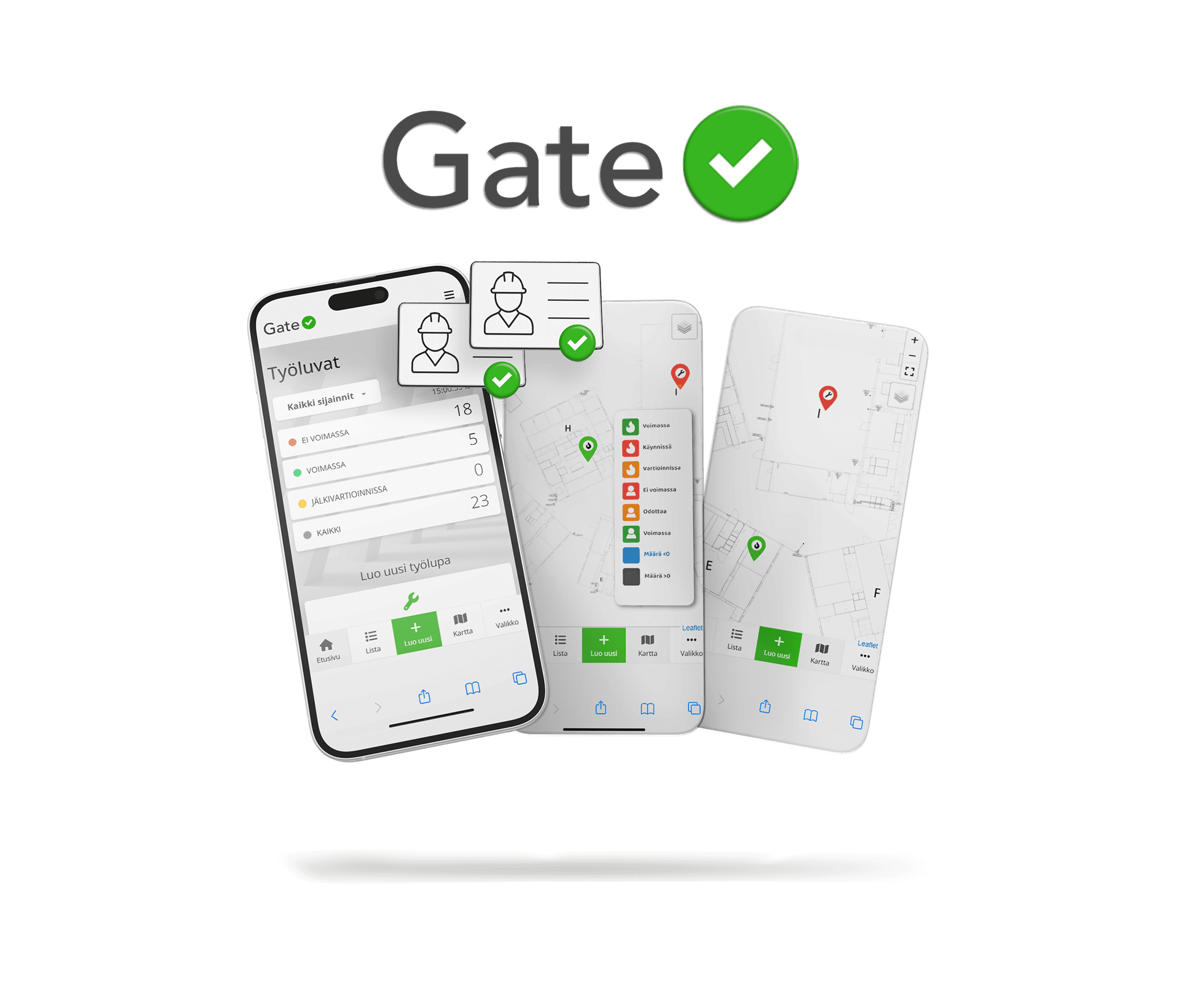

Gate Apps’ Permit-to-Work Management System is one such digital solution. Designed for industrial and construction settings with large volumes of permit-controlled work, it covers permit creation, competency checks, validity tracking and archiving.

Key benefits of an electronic PTW system

Uniform practices across the organisation

When one electronic system is in use, the entire company—or at least the whole site or plant—operates under the same rules. All supervisors and contractors use identical digital forms and workflows. This cuts variation: each permit asks the same essential questions and requires the same checks. Consistency lifts quality—no part of the permit is overlooked simply because someone forgot it; the system prompts for every item.Immediate availability and data sharing

In a digital system, permit information moves in seconds. If a maintenance engineer issues a confined-space permit, the attendant and supervisor see it instantly on their devices, so work need not wait for paperwork. Other stakeholders can view permits when necessary: the control room can monitor which equipment is down under permits, or a client can check a subcontractor’s permit status. All of this improves coordination and helps prevent dangerous overlaps.Enhanced safety

The system guards against “dark” work—jobs started without a permit—because the process is simple and visible. Compliance with conditions is easier to monitor: required checkpoints can be set as mandatory before approval (e.g. “is energy isolation complete?” or “has a fire watch been appointed?”). Such controls act as checklists and are far more reliable than memory. The system also records who approved the permit and when—responsibilities are clearer, and people act more diligently knowing their name is logged as approver.Efficiency and cost savings

Safety comes first, but efficiency matters too. An electronic PTW system reduces administrative work. Creating a permit takes less time, searching information is quick (search function versus rifling through binders) and double entry disappears. A site engineer who once compiled a weekly Excel list of permits for reporting can now have the system generate it automatically. Faster permits mean workers spend less time waiting, leading to shorter downtime and higher productivity. Over time, fewer accidents also yield major savings—good permit control helps prevent incidents.Audit trail

Every action leaves a digital trace—an invaluable advantage internally and externally. Internally, if something goes wrong, you can see exactly what happened in the permit process (did the approval chain break, was the risk assessment completed). Externally, you can prove to regulators or customers: “Here is how this permit was handled—see the records.” The audit trail builds trust: employees know that every permit activity is recorded, encouraging adherence to procedures.Scalability and versatility

A digital system scales with organisational size and need. Whether there are a few dozen permits a month or thousands, the same platform copes. Paper would become unwieldy on a large scale. The system also lets you add new permit types easily. If the business introduces a task that needs a permit (e.g. drone flights on a plant site), you can create a dedicated form and workflow swiftly.

Electronic vs paper: practical comparisons

Changing conditions – If permit conditions change mid-job (say, weather shifts and a new precaution is needed), an approver can update the condition in the system and it appears instantly on everyone’s permit record. Collecting and revising distributed paper copies is nearly impossible.

Multilingual environments – On international or multilingual sites the system can display permit details in different languages for different users. A worker sees instructions in his own language even if the supervisor entered them in Finnish—crucial for safety in multicultural teams.

Contractor management – External contractors can be given limited access. They submit their own requests, view their permits and acknowledge them. The host company retains control, setting conditions and granting approvals. Policing contractor permits on paper is far harder.

Information security – Paper permits can be lost or damaged. Digital records are backed up and access-controlled. Confidential permits (e.g. certain radiation or blasting work) remain visible only to authorised roles.

Environmental friendliness – Paperless operation saves paper, printing costs and transport—aligning with many organisations’ sustainability goals.

Starting the switch to an electronic PTW system

Change usually begins with a pilot project. Choose one site or one permit type and trial the system there. Train users and fine-tune the workflow. Once results are positive, roll out gradually. Securing buy-in from employees and supervisors is essential—resistance fades quickly once they experience the benefits (less paperwork, faster communication).

Gate Apps’ electronic PTW system is cloud-based, so deployment is light: users need only credentials and a browser or mobile app. Built in collaboration with Finnish industrial companies, it reflects local practices and requirements (hot-work card validations, Finnish-language forms, etc.). Support helps you get started and, when needed, integrate with other systems.

Summary: take the digital leap in permit management

An electronic permit-to-work system is a modern answer to an old challenge: ensuring that high-risk jobs are carried out safely, efficiently and systematically. Digitising the permit process raises safety levels, streamlines operations and improves communication. Management gains stronger tools to monitor and develop activities using data.

Many forward-thinking companies have already moved to electronic permits—and rarely look back. After experiencing the ease and reliability of a digital system, traditional binders and paper slips feel decidedly outdated.